leaning Is

Cleaning building façades—especially in skyscrapers—has historically been a dangerous, slow, and expensive task. Most high-rise buildings still rely on workers suspended from gondolas or ropes, exposed to falls, harsh weather conditions, and long work hours. In this context, automation has become a much-needed and urgent solution.

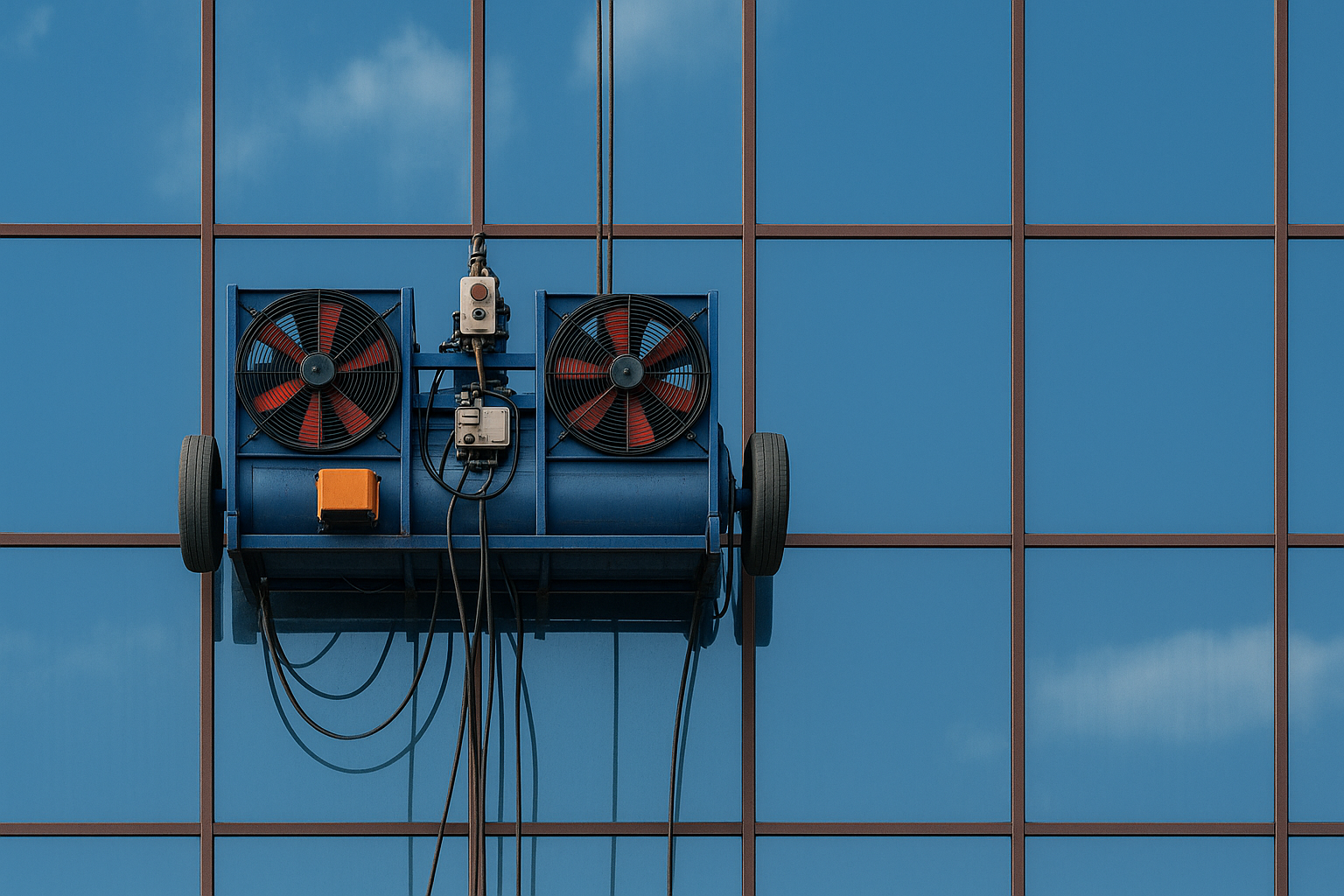

Recently, researchers from Hanyang University in South Korea introduced an innovative high-pressure water cleaning technique integrated into a wall-climbing robot. This advancement aims not only to improve efficiency but also to drastically reduce the risks associated with façade cleaning.

The Problem: Cleaning an Increasing Number of Tall Buildings

As the construction of high-rise buildings accelerates worldwide, exterior maintenance has become a major challenge. Traditional cleaning methods present several disadvantages:

- High risk to workers

- Uncleaned patches due to frames, ornaments, or façade irregularities

- Slow operation, especially for robots that rely on suction or low-speed movement

- High operational costs

High-pressure water systems integrated into robotic platforms are emerging as a promising alternative.

The Proposed Solution: A Robot That Cleans Using High-Pressure Water

The study describes a cable-driven, winch-based robot equipped with:

- A high-pressure water cleaning module

- A propeller system to keep the robot attached to the wall

- Optimized spray nozzles

- A pressure sensor

- A guide wall to avoid recontamination

This robot descends vertically while spraying high-pressure water, even when obstacles such as window frames are present. Because the system does not require direct contact with the glass or wall surface, wear is reduced and blind spots are minimized.

Why High-Pressure Water Makes a Difference

Compared to suction-based or brush-based robots, high-pressure water cleaning provides:

- Greater coverage, even on irregular surfaces

- Elimination of uncleaned zones thanks to adjustable spray direction

- Reduced mechanical wear and lower surface damage risk

- Simpler mechanical design and easier maintenance

Nozzle type and operating parameters are key to achieving uniform, effective cleaning.

Optimizing the Cleaning System: What Were the Most Important Parameters?

The researchers used the Taguchi optimization method, a statistical approach that allows efficient testing of multiple variables with minimal experiments.

The parameters evaluated were:

- Inlet pressure at the nozzle (3, 6, 8 bar)

- Spray distance (200, 300, 400 mm)

- Spray angle (15°, 25°, 40°)

- Robot descent speed (3 and 6 m/min)

After multiple tests and an image-based analysis comparing the surface before and after cleaning, the study revealed that:

The most influential factors—ranked by importance—were:

- Water pressure

- Spray distance

- Spray angle

The robot’s descent speed affects results, but significantly less than the core parameters above.

The Best Results: Optimal Cleaning Parameters

The study concluded that the ideal conditions for maximum cleaning efficiency are:

- Pressure: 8 bar

- Distance: 200 mm

- Angle: 40°

- Speed: 3 m/min

Under these conditions, the robot achieved the highest surface-cleaning effectiveness with a uniform spray distribution and efficient removal of contaminants.

Is High-Pressure Water Safe for Building Surfaces?

Yes. Force measurements showed that:

- Reaction force at the nozzle: ~2.6 N

- Impact force on the surface: ~2.7 N

These values are far below levels that could damage the façade or interfere with the robot’s adherence to the wall. This makes the system compatible with standard building materials.

What This Means for the Future of Building Cleaning

This technology opens the door to safer, more efficient, and more adaptable cleaning robots. Its potential impacts include:

- Reducing workplace accidents

- Lowering operational costs

- Increasing cleaning speed

- Adapting to complex building geometries

- Improving overall cleaning quality

Future developments include:

- Testing with optimized control algorithms

- Evaluating performance when navigating real obstacles

- Integrating the system into commercial robotic platforms

Acknowledgments and Credits

This article is entirely based on the research published in PLOS ONE titled:

“Automated technique for high-pressure water-based window cleaning and accompanying parametric study”

by Youngjoo Lee, Daesung Kwon, Changmin Park, Myoungjae Seo, and TaeWon Seo,

from the School of Mechanical Engineering, Hanyang University, South Korea.

We express our gratitude to the authors for their rigorous scientific work and for making their findings accessible through open access, enabling this translation and dissemination in a blog-friendly format.