Introduction

A country’s power grid may seem invisible… until it fails.

Behind every transmission line there are maintenance teams who spend hours inspecting and cleaning critical components. One of them, almost always ignored, is the string of insulators: those “plates” of glass or porcelain that separate the conductor from the tower.

When these insulators get covered with salt, dust, or bird droppings, they become a silent threat: they can cause discharges, trip protections, and leave thousands of users without power. Traditionally, cleaning them means either a technician climbing the tower or a helicopter approaching at full voltage. Risky? Very.

A group of researchers from the Federal University of Uberlândia (Brazil) and the utility company CELESC decided to change this story with a powerful idea: using a drone to wash energized insulators in a safe and controlled way.

The Problem of Dirty Insulators

Insulators are designed to withstand voltages of up to hundreds of kV. But over time they become covered with:

- Salt (coastal areas)

- Dust and ash

- Bird droppings

- Industrial and vehicle smoke, chemicals, etc.

This mixture forms a slightly conductive film. If combined with fog, light rain, or high humidity, the risk of flashover increases: a sudden discharge that “jumps” across the surface of the insulator. The result can be:

- Power supply interruptions

- Damage to industrial and residential equipment

- In the worst case, fires and accidents

That’s why utilities schedule periodic washing of insulators. The problem is how it is done today.

From Rags and Helicopters to Drones

Traditional methods include:

- Technicians climbing towers with rags or pressure washers

- Trucks with elevated platforms on distribution lines

- Helicopters with high-pressure washers for large transmission lines

These methods have three major drawbacks:

- Human risk: falls from height, proximity to energized lines, helicopter crashes, etc.

- Cost: fuel, maintenance, insurance, salaries for specialized pilots.

- Logistics: need for multiple people, travel time, weather constraints.

The drone appears as an intermediate solution: cheaper and more agile than a helicopter, less risky than sending a person right next to the insulator.

What Is the Drone for Cleaning Insulators?

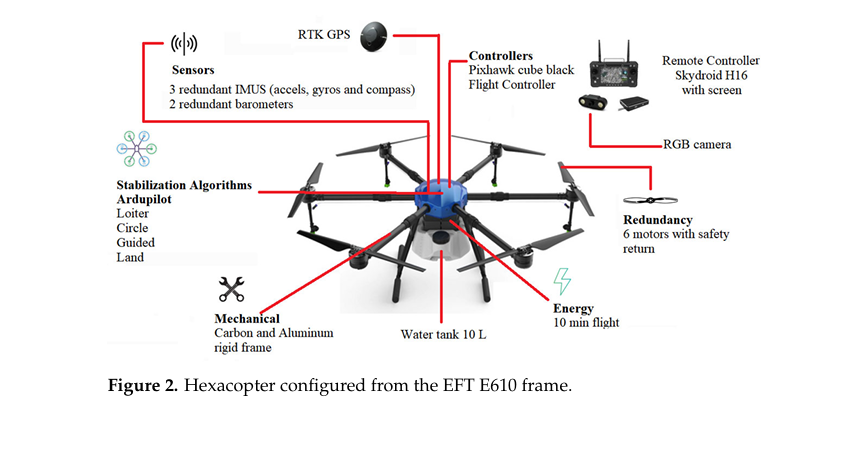

The system proposed in the article is a hexacopter (six rotors) equipped with a robotic cleaning module.

In Figure 2 of the article (p. 5), you can see the base drone, originally designed for agricultural spraying, with:

- EFT E610 frame, tank capacity up to 10 L

- Pixhawk flight controller with Ardupilot firmware, which keeps the drone stable (Loiter mode)

- RTK GPS for precise positioning

On top of this platform, the team mounted a cleaning module that includes:

- Portable pressure washer (320 psi, 1.6 L/min)

- 8 L tank of demineralized water

- Front RGB camera (so the pilot can see what’s happening)

- Intel RealSense D435 depth camera (to measure the exact distance to the insulator)

- Raspberry Pi 3B+ that coordinates the system, the actuators that pull the washer trigger, and the wireless communication

Thus, the pilot on the ground:

- Flies the drone up to the tower and positions it in front of the insulator string using the RGB camera.

- Activates assistance mode: the depth camera calculates the distance to the string.

- When the drone is between 1 and 1.5 meters away, the system warns the pilot with acoustic signals and the pressure washer is activated.

Safety First: Water, Distance, and Shielding

Bringing a drone full of electronics close to a 138 kV line is no game. The project carefully addressed three key aspects:

- Type of water:

- Demineralized water is used, with very low conductivity (<10 µS) and controlled pH, so that the jet does not create a conductive path between the line and the drone.

- Safety distance:

- Tests showed that washing is effective at distances between 1.0 and 1.5 m: close enough to clean, far enough to avoid discharges and collisions.

- Electromagnetic shielding:

- Sensitive electronics (washer control, communication, etc.) are housed in aluminum enclosures.

- Using electromagnetic compatibility models, the team calculated the attenuation of electric and magnetic fields across different frequency ranges. The result: the fields reaching the inside are on the order of nanovolts per centimeter, negligible compared to typical electronics levels of 5–11 V.

In field tests, the drone behaved in a stable way and there were no visible interferences in its flight control or in triggering the pressure washer.

Does It Really Work? – Lab and Field Results

In the lab

- They set up a string of 10 glass discs and covered it with a 35% salt solution (more concentrated than usual to make the challenge harder).

- The drone positioned itself in front of the string, activated the water jet, and performed vertical and lateral sweeps.

In the field

- The drone was tested on an energized 138 kV line, positioning in front of the insulators and operating the washer under real conditions.

The tests showed that the system is capable of effectively cleaning the insulator surfaces while maintaining safe distances and stable operation of the drone and its electronics.

This blog post is based on the article “Drone–Robot to Clean Power Line Insulators” by R. S. Gonçalves, M. De Oliveira, M. Rocioli, F. Souza, C. Gallo, D. Sudbrack, P. Trautmann, B. Clasen, and R. Homma, published in Sensors 23, 5529 (2023). The technical information and data presented here are adapted from that work, and any interpretations or emphasis are my own. DOI: 10.3390/s23125529.